Related Publications by the GEG Group

REFEREED PUBLICATIONS IN JOURNALS

Rossi, E. ,

M.O. Saar, and

Ph. Rudolf von Rohr,

The influence of thermal treatment on rock-bit interaction: a study of a combined thermo-mechanical drilling (CTMD) concept, Geothermal Energy, 8/16,

2020.

https://doi.org/10.1186/s40517-020-00171-y [Download] [View Abstract]To improve the economics and viability of accessing deep georesources, we propose a combined thermo–mechanical drilling (CTMD) method, employing a heat source to facilitate the mechanical removal of rock, with the aim of increasing drilling performance and thereby reducing the overall costs, especially for deep wells in hard rocks. In this work, we employ a novel experiment setup to investigate the main parameters of interest during the interaction of a cutter with the rock material, and we test untreated and thermally treated sandstone and granite, to understand the underlying rock removal mechanism and the resulting drilling performance improvements achievable with the new approach. We find that the rock removal process can be divided into three main regimes: first, a wear-dominated regime, followed by a compression-based progression of the tool at large penetrations, and a final tool fall-back regime for increasing scratch distances. We calculate the compressive rock strengths from our tests to validate the above regime hypothesis, and they are in good agreement with literature data, explaining the strength reduction after treatment of the material by extensive induced thermal cracking of the rock. We evaluate the new method’s drilling performance and confirm that thermal cracks in the rock can considerably enhance subsequent mechanical rock removal rates and related drilling performance by one order of magnitude in granite, while mainly reducing the wear rates of the cutting tools in sandstone.

Rossi, E.,

S. Jamali,

V. Wittig,

M.O. Saar, and

Ph. Rudolf von Rohr,

A combined thermo-mechanical drilling technology for deep geothermal and hard rock reservoirs, Geothermics, 85/101771,

2020.

https://doi.org/10.1016/j.geothermics.2019.101771 [Download] [View Abstract]Combined thermo-mechanical drilling is a novel technology to enhance drilling performance in deep hard rock formations. In this work, we demonstrate this technology in the field by implementing the concept on a full-scale drilling rig, and we show its feasibility under realistic process conditions. We provide evidence that the novel drilling method can increase the removal performance in hard rocks by up to a factor of three, compared to conventional drilling methods. From the findings of this work, we conclude that integration of thermal assistance to conventional rotary drilling constitutes an interesting approach to facilitate the drilling process, and therefore increase the access viability to deep georesources in hard rocks.

Rossi, E.,

S. Jamali,

M.O. Saar, and

Ph. Rudolf von Rohr,

Field test of a Combined Thermo-Mechanical Drilling technology. Mode I: Thermal spallation drilling, Journal of Petroleum Science and Engineering, 190/107005,

2020.

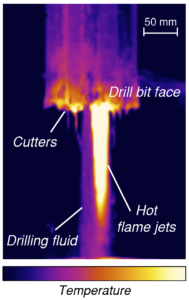

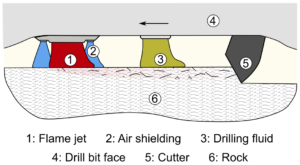

https://doi.org/10.1016/j.petrol.2020.107005 [Download] [View Abstract]Accessing hydrocarbons, geothermal energy and mineral resources requires more and more drilling to great depths and into hard rocks, as many shallow resources in soft rocks have been mined already. Drilling into hard rock to great depths, however, requires reducing the effort (i.e., energy), time (i.e., increasing the rate of penetration) and cost associated with such operations. Thus, a Combined Thermo-Mechanical Drilling (CTMD) technology is proposed, which employs a heat source (e.g., a flame jet) and includes two main drilling modes: (I) Thermal spallation drilling, investigated here as a field test and (II) Flame-assisted rotary drilling, investigated as a field test in the companion paper. The CTMD technology is expected to reduce drilling costs, especially in hard rocks, by enhancing the rock penetration rate and increasing the bit lifetime. Mode I of the CTMD technology (thermal spallation drilling) is investigated here by implementing the concept on a full-scale drilling rig to investigate its feasibility and performance under realistic field conditions. During the test, the successful thermal spallation process is monitored, employing a novel acoustic emission system. The effects of thermal spallation in the granite rock are analyzed to provide conclusions regarding the rock removal performance and the application potential of the technology. The field test shows that thermal spallation of the granitic rock can be successfully achieved even when a liquid (water) is used as the drilling fluid, as long as the heat source is appropriately shielded by compressed-air jets. Thermal damage of the surrounding rock is investigated after the spallation test, employing micro-computer tomography imaging and modeling the stability of the cracks, generated by the spallation field test. This study shows that thermally induced damage is mainly confined within a narrow region close to the rock surface, suggesting that thermal spallation only marginally affects the overall mechanical stability of the borehole. Thus, this confirms that, as part of the Combined Thermo- Mechanical Drilling (CTMD) technology, thermal spallation drilling is a promising mode that has a high potential of facilitating the drilling of deep boreholes in hard rocks.

Rossi, E.,

S. Jamali,

D. Schwarz,

M.O. Saar, and

Ph. Rudolf von Rohr,

Field test of a Combined Thermo-Mechanical Drilling technology. Mode II: Flame-assisted rotary drilling, Journal of Petroleum Science and Engineering, 190/106880,

2020.

https://doi.org/10.1016/j.petrol.2019.106880 [Download] [View Abstract]To enhance the drilling performance in deep hard rocks and reduce overall drilling efforts, this work proposes a Combined Thermo-Mechanical Drilling (CTMD) technology. This technology employs a heat source (e.g., a flame jet) and includes two main drilling modes: (I) thermal spallation drilling, investigated in the companion paper and (II) flame-assisted rotary drilling, investigated here as a field test. The CTMD technology is expected to reduce drilling efforts, especially in hard rocks, enhancing the rock penetration rate and increasing the bit lifetime, all of which reduces the drilling costs. The present work investigates Mode II (flame-assisted rotary drilling) of the CTMD technology by implementing the concept in an existing drilling rig and testing the technology under relevant process conditions. This contribution studies the underlying rock removal mechanism of CTMD and demonstrates its drilling performance, compared to conventional rotary drilling methods. Acoustic emission monitoring, and analysis of the collected drill cuttings provide multiple evidences for thermal-cracking-enhanced rock removal during the flame-assisted rotary drilling. This removal mechanism appears to represent an optimal compromise to minimize rock fragmentation and cutting transport efforts during drilling, compared to a less efficient mechanical scraping of the hard granite rock, observed during the standalone-mechanical drill test. The drilling performance, in terms of removal and wear rates, are evaluated for the flame-assisted rotary drilling. This shows that the proposed drilling approach is capable of enhancing the removal process in hard granite rock, by a factor of 2.5, compared to standalone-mechanical drilling. The implementation of this drilling approach into a conventional drilling system shows that integration of thermal assistance to conventional rotary drilling requires marginal technical efforts. Additionally, this technology can profit from established knowledge in conventional mechanical drilling, facilitating its implementation to improve drilling performance in hard rocks. Hence, this study demonstrates that the Combined Thermo- Mechanical Drilling method is feasible and concludes that this technology constitutes a promising approach to improve the drilling process, thereby increasing the viability of accessing deep geo-resources in hard rocks.

Rossi, E.,

M.A. Kant,

C. Madonna,

M.O. Saar, and

Ph. Rudolf von Rohr,

The Effects of High Heating Rate and High Temperature on the Rock Strength: Feasibility Study of a Thermally Assisted Drilling Method, Rock Mechanics and Rock Engineering, 51/9, pp. 2957-2964 ,

2018.

https://doi.org/10.1007/s00603-018-1507-0 [Download] [View Abstract]In this paper, the feasibility of a thermally assisted drilling method is investigated. The working principle of this method is based on the weakening effect of a flame-jet to enhance the drilling performance of conventional, mechanical drilling. To investigate its effectiveness, we study rock weakening after rapid, localized flame-jet heating of Rorschach sandstone and Central Aare granite. We perform experiments on rock strength after flame treatments in comparison to oven heating, for temperatures up to 650 \(^{\circ} \)C and heating rates from 0.17 to 20 \(^{\circ} \)C/s. The material hardening, commonly observed at moderate temperatures after oven treatments, can be suppressed by flame heating the material at high heating rates. Our study highlights the influence of the heating rate on the mechanism of thermal microcracking. High heating rate, flame treatments appear to mostly induce cracks at the grain boundaries, opposed to slow oven treatments, where also a considerable number of intragranular cracks are found. Herewith, we postulate that at low heating rates, thermal expansion stresses cause the observed thermal cracking. In contrast, at higher heating rates, thermal cracking is dominated by the stress concentrations caused by high thermal gradients.

PROCEEDINGS REFEREED

Rossi, E.,

B. Adams,

D. Vogler,

Ph. Rudolf von Rohr,

B. Kammermann, and

M.O. Saar,

Advanced drilling technologies to improve the economics of deep geo-resource utilization, Proceedings of Applied Energy Symposium: MIT A+B, United States, 2020 , 8, pp. 1-6,

2020. https://doi.org/10.3929/ethz-b-000445213 [Download] [View Abstract]Access to deep energy resources (geothermal energy, hydrocarbons) from deep reservoirs will play a fundamental role over the next decades. However, drilling of deep wells to extract deep geo-resources is extremely expensive. As a fact, drilling deep wells into hard, crystalline rocks represents a major challenge for conventional rotary drilling systems, featuring high rates of drill bit wear and requiring frequent drill bit replacements, low penetration rates and poor process efficiency. Therefore, with the aim of improving the overall economics to access deep geo-resources in hard rocks, in this work, we focus on two novel drilling methods, namely: the Combined Thermo-Mechanical Drilling (CTMD) and the Plasma-Pulse Geo-Drilling (PPGD) technologies. The goal of this research and development project is the effective reduction of the costs of drilling in general and particularly regarding accessing and using deep geothermal energy, oil or gas resources. In this work, we present these two novel drilling technologies and focus on evaluating the process efficiency and the drilling performance of these methods, compared to conventional rotary drilling.

References

Diaz, M.B., Kim, K.Y., Kang, T.-H., Shin, H.-S.: Drilling data from an en- hanced geothermal project and its pre-processing for ROP forecasting improvement. Geothermics, 72, (2017), 348-357.

Fay, H.: Practical evaluation of rock-bit wear during drilling. SPE Drilling & Completion, 8(2), (1993), 99-104.

Kant, M., Rossi, E., Madonna, C., Höser, D., Rudolf von Rohr, Ph.: A theory on thermal spalling of rocks with a focus on thermal spallation drilling. Journal of Geophysical Research: Solid Earth, 122(3), (2017), 1805–1815.

Lukawski, M., Anderson, B., Augustine, C., Capuano, L.E., Beckers, K.F., Livesay, B., Tester, J.W.: Cost analysis of oil, gas and geothermal well drilling. Journal of Petroleum Science and Engineering, 118, (2014), 1-14.

Rauenzahn, R., Tester, J.: Rock failure mechanisms of flame-jet thermal spallation drilling theory and experimental testing. International Journal of Rock Mechanics and Mining Sciences and Geomechanics Abstracts, 26(5), (1989), 381-399.

Sigfusson, B., Uihlein, A.: 2015 JRC Geothermal Energy Status Report. EUR 27623 EN, (2015), p. 60.

Stefánsson, V.: Success in geothermal development. Geothermics, 21(5/6), (1992), 823-834.

Tester, J.W., Anderson, B., Batchelor, A., Blackwell, D., DiPippo, R., Drake, E., Garnish, J., Livesay, B., Moore, M.C., Nichols, K.: The Future of Geothermal Energy. Technical Report, Idaho National Laboratory, (2006).