Description

Introduction

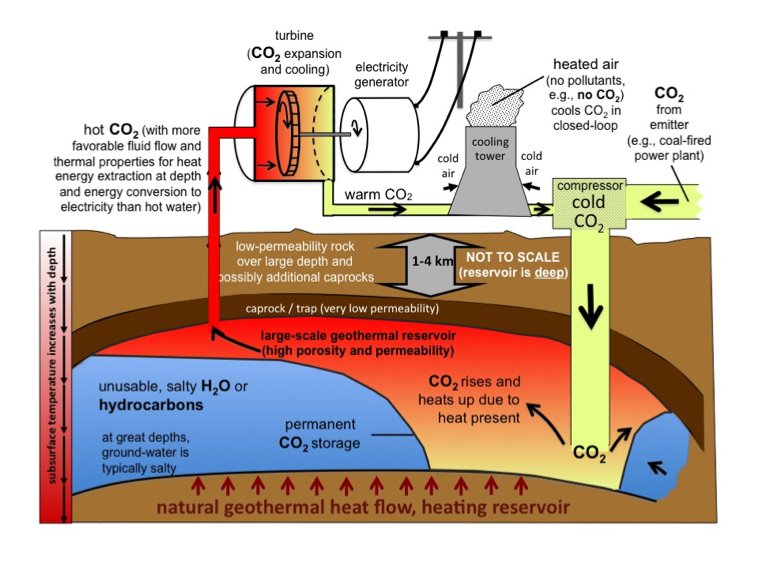

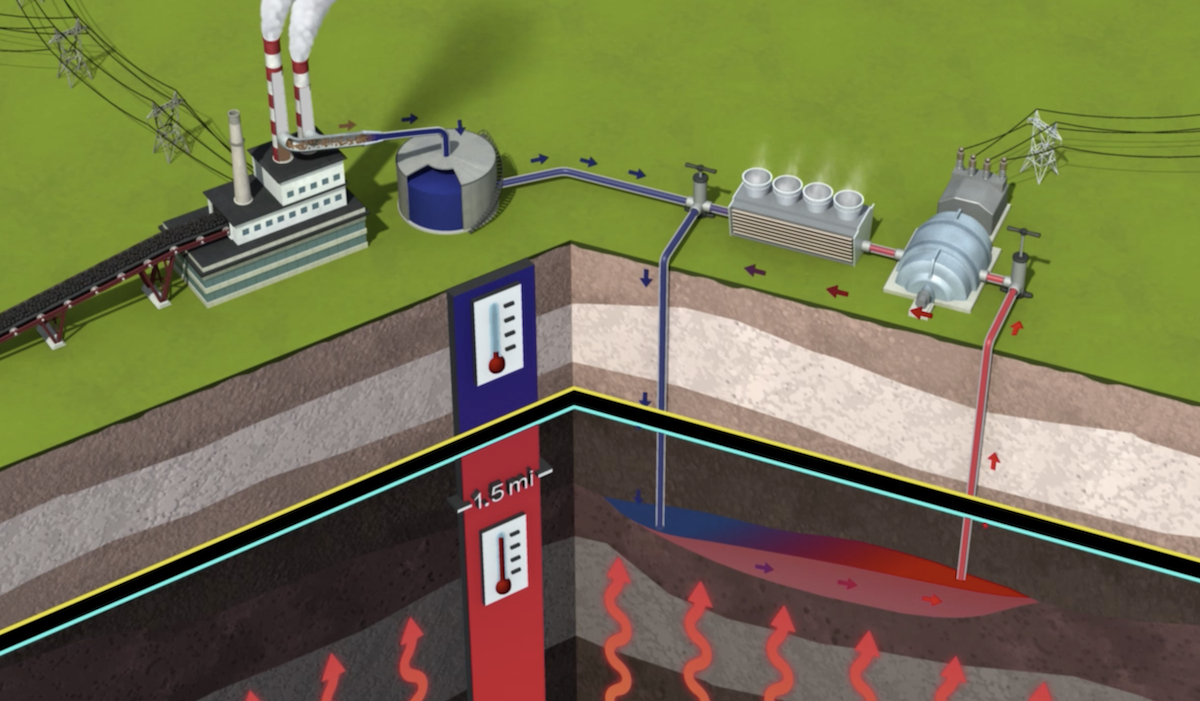

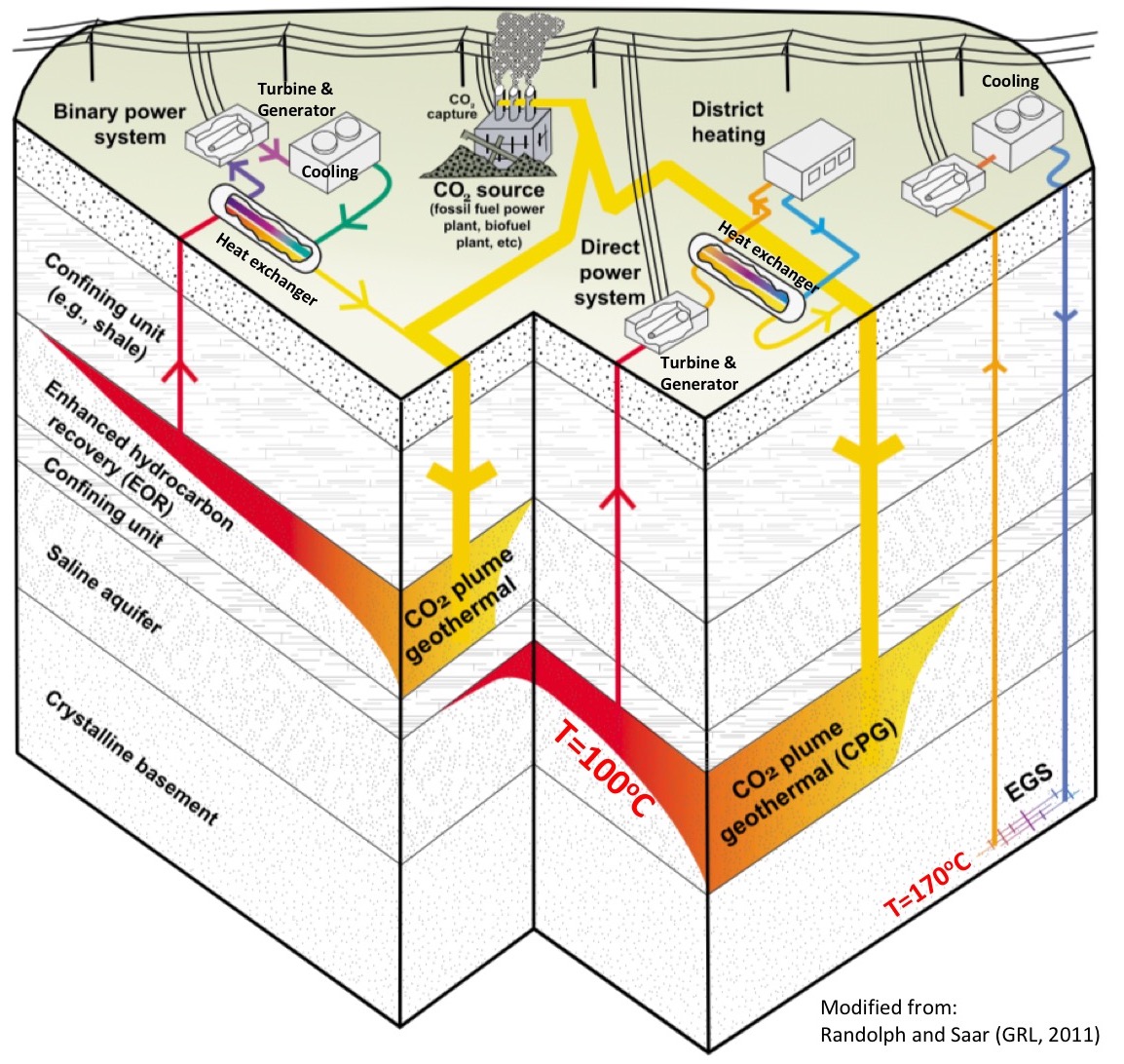

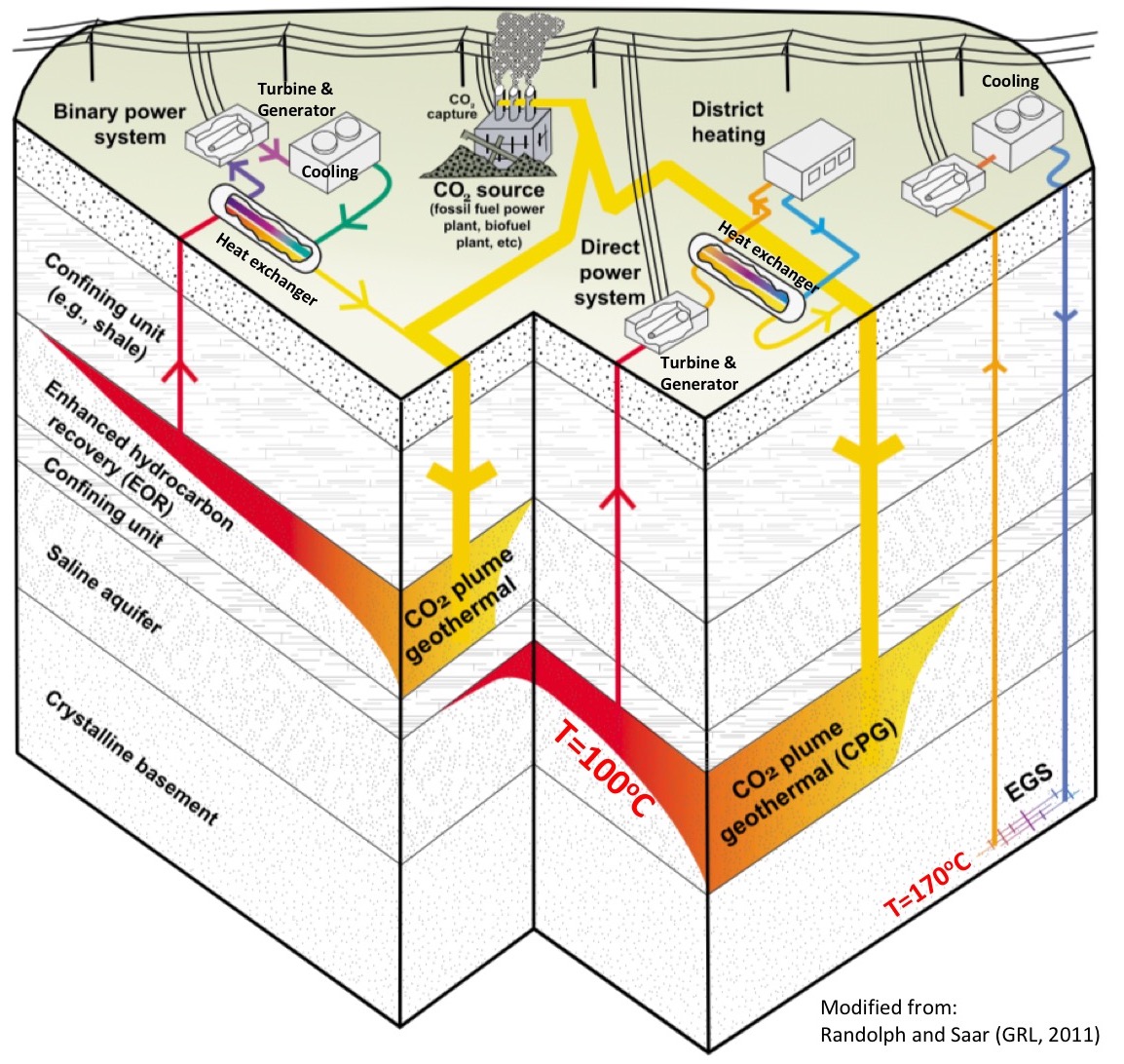

CO2 Plume Geothermal systems (CPG) (Randolph and Saar, 2011a, b; Saar et al., 2012; Buscheck et al., 2013), involve injection of CO2 that has been captured at a CO2 emitter (e.g. cement manufacturer, biofuel refinery, fossil-fuelled power plant) as a working fluid into an underground reservoir (deep saline formation or oil/gas reservoir) to extract heat and pressure energy (enthalpy) from naturally high-permeability sedimentary basins. The injected CO2 forms a large subsurface CO2 plume and permanently sequesters the CO2 underground. As more CO2 is injected, the CO2 plume continues to grow. The subsurface CO2 absorbs heat from the reservoir rocks. Given a sufficient pore-space CO2 saturation at a given reservoir location, the geothermal heated CO2 can be produced from that location to the land surface, used as direct heat or converted to electricity, cooled and condensed, and the reinjected into the original reservoir, closing the loop and ensuring that 100% of the originally injected CO2 is eventually still permanently sequestered underground (Randolph and Saar, 2011a; Saar et al., 2012; Adams et al., 2014, 2015).

CO2-Plume Geothermal (CPG) systems can be combined with Carbon Capture and Storage (CCS), constituting a Carbon Capture Utilization and Storage (CCUS) system, or with Enhanced Oil or Gas Recovery (EOR/EGR). CPG systems can be direct, where the produced CO2 passes directly through a specialized CO2 turbine, or indirect, where a secondary power cycle is employed to generate electricity. Shown for comparison is also an Enhanced Geothermal System (EGS), where the permeability of hot but low-permeability crystalline basement rock is enhanced through hydraulic stimulation. Such EGS are much smaller in overall size and fluid flow is confined to fractures, so that significantly less geothermal energy can be extracted from such EGS, despite exhibiting higher temperatures that CPG systems.

CO2-Plume Geothermal (CPG) systems can be combined with Carbon Capture and Storage (CCS), constituting a Carbon Capture Utilization and Storage (CCUS) system, or with Enhanced Oil or Gas Recovery (EOR/EGR). CPG systems can be direct, where the produced CO2 passes directly through a specialized CO2 turbine, or indirect, where a secondary power cycle is employed to generate electricity. Shown for comparison is also an Enhanced Geothermal System (EGS), where the permeability of hot but low-permeability crystalline basement rock is enhanced through hydraulic stimulation. Such EGS are much smaller in overall size and fluid flow is confined to fractures, so that significantly less geothermal energy can be extracted from such EGS, despite exhibiting higher temperatures that CPG systems.

The heat density of sedimentary basins is typically relatively low. However, this drawback can be counteracted by the large accessible pore-space volume of natural reservoirs, compared to the relatively small reservoirs developed artificially by hydraulic stimulation (Dezayes et al., 2005). Furthermore, supercritical CO2 has a high mobility (i.e., low kinematic viscosity) and high thermal expansibility, compared to water, resulting in the formation of a strong thermosiphon, which eliminates the need for parasitic pumping power requirements.

Three-dimensional (3D), axisymmetric model with a cross section of the CO2-Plume Geothermal (CPG) reservoir showing grid discretization and placement of wells.

Three-dimensional (3D), axisymmetric model with a cross section of the CO2-Plume Geothermal (CPG) reservoir showing grid discretization and placement of wells.

The thermosiphon effect and in particular the high mobility of CO2 significantly increase the electric power production efficiency of the geothermal system, compared to water-based geothermal systems. The produced electric power can then, for example, be used to drive the CO2 injection pumps and/or the CO2 capture facility if geologic CO2 capture and storage is ongoing or and/it could be supplied to the electric power grid to generate revenue. Similarly, produced heat could be directly used, if a heat consumer exists nearby, for example the CO2capture facility. Because the produced CO2 is reinjected into the original geothermal reservoir with the main CO2 sequestration stream, coming from the CO2 emitter, all of the CO2 is ultimately geologically sequestered resulting in a CO2 sequestering geothermal power plant. Alternatively, when geologic CO2 storage is uneconomic, CPG systems could also be operated with a limited, finite amount of CO2, stored underground, and thereafter run with little or no additional makeup CO2.

Related Publications by the GEG Group

REFEREED PUBLICATIONS IN JOURNALS

van Brummen, A.C.,

B.M. Adams,

R. Wu,

J.D. Ogland-Hand, and

M.O. Saar,

Using CO2-Plume Geothermal (CPG) Energy Technologies to Support Wind and Solar Power in Renewable-Heavy Electricity Systems, Renewable and Sustainable Energy Transition, 2,

2022.

https://doi.org/10.1016/j.rset.2022.100026 [Download] [View Abstract]CO2-Plume Geothermal (CPG) technologies are geothermal power systems that use geologically stored CO2 as the subsurface heat extraction fluid to generate renewable energy. CPG technologies can support variable wind and solar energy technologies by providing dispatchable power, while Flexible CPG (CPG- F) facilities can provide dispatchable power, energy storage, or both simultaneously. We present the first study investigating how CPG power plants and CPG-F facilities may operate as part of a renewable- heavy electricity system by integrating plant-level power plant models with systems-level optimization models. We use North Dakota, USA as a case study to demonstrate the potential of CPG to expand the geothermal resource base to locations not typically considered for geothermal power. We find that optimal system capacity for a solar-wind-CPG model can be up to 20 times greater than peak- demand. CPG-F facilities can reduce this modeled system capacity to just over 2 times peak demand by providing energy storage over both seasonal and short-term timescales. The operational flexibility of CPG-F facilities is further leveraged to bypass the ambient air temperature constraint of CPG power plants by storing energy at critical temperatures. Across all scenarios, a tax on CO2 emissions, on the order of hundreds of dollars per tonne, is required to financially justify using renewable energy over natural-gas power plants. Our findings suggest that CPG and CPG-F technologies may play a valuable role in future renewable-heavy electricity systems, and we propose a few recommendations to further study its integration potential.

Fleming, M.R.,

B.M. Adams,

J.D. Ogland-Hand,

J.M. Bielicki,

T.H. Kuehn, and

M.O. Saar,

Flexible CO2-Plume Geothermal (CPG-F): Using Geologically Stored CO2 to Provide Dispatchable Power and Energy Storage, Energy Conversion and Management, 253/115082,

2022.

https://doi.org/10.1016/j.enconman.2021.115082 [Download] [View Abstract]CO2-Plume Geothermal (CPG) power plants can use geologically stored CO2 to generate electricity. In this study, a Flexible CO2 Plume Geothermal (CPG-F) facility is introduced, which can use geologically stored CO2 to provide dispatchable power, energy storage, or both dispatchable power and energy storage simultaneously—providing baseload power with dispatchable storage for demand response. It is found that a CPG-F facility can deliver more power than a CPG power plant, but with less daily energy production. For example, the CPG-F facility produces 7.2 MWe for 8 hours (8h-16h duty cycle), which is 190% greater than power supplied from a CPG power plant, but the daily energy decreased by 61% from 60 MWe-h to 23 MWe-h. A CPG-F facility, designed for varying durations of energy storage, has a 70% higher capital cost than a CPG power plant, but costs 4% to 27% more than most CPG-F facilities, designed for a specific duration, while producing 90% to 310% more power than a CPG power plant. A CPG-F facility, designed to switch from providing 100% dispatchable power to 100% energy storage, only costs 3% more than a CPG-F facility, designed only for energy storage.

Ezekiel, J.,

B.M. Adams,

M.O. Saar, and

A. Ebigbo,

Numerical analysis and optimization of the performance of CO2-Plume

Geothermal (CPG) production wells and implications for electric power

generation, Geothermics, 98/102270,

2022.

https://doi.org/10.1016/j.geothermics.2021.102270 [Download] [View Abstract]CO2-Plume Geothermal (CPG) power plants can produce heat and/or electric power. One of the most important parameters for the design of a CPG system is the CO2 mass flowrate. Firstly, the flowrate determines the power generated. Secondly, the flowrate has a significant effect on the fluid pressure drawdown in the geologic reservoir at the production well inlet. This pressure drawdown is important because it can lead to water flow in the reservoir towards and into the borehole. Thirdly, the CO2 flowrate directly affects the two-phase (CO2 and water) flow regime within the production well. An annular flow regime, dominated by the flow of the CO2 phase in the well, is favorable to increase CPG efficiency. Thus, flowrate optimizations of CPG systems need to honor all of the above processes. We investigate the effects of various operational parameters (maximum flowrate, ad- missible reservoir-pressure drawdown, borehole diameter) and reservoir parameters (permeability anisotropy and relative permeability curves) on the CO2 and water flow regime in the production well and on the power generation of a CPG system. We use a numerical modeling approach that couples the reservoir processes with the well and power plant systems. Our results show that water accumulation in the CPG vertical production well can occur. However, with proper CPG system design, it is possible to prevent such water accumulation in the pro- duction well and to maximize CPG electric power output.

Ezekiel, J.,

D. Kumbhat,

A. Ebigbo,

B.M. Adams, and

M.O. Saar,

Sensitivity of Reservoir and Operational Parameters on the Energy Extraction Performance of Combined CO2-EGR–CPG Systems, Energies, 14/6122,

2021.

https://doi.org/10.3390/en14196122 [Download] [View Abstract]There is a potential for synergy effects in utilizing CO2 for both enhanced gas recovery (EGR) and geothermal energy extraction (CO2-plume geothermal, CPG) from natural gas reservoirs. In this study, we carried out reservoir simulations using TOUGH2 to evaluate the sensitivity of natural gas recovery, pressure buildup, and geothermal power generation performance of the combined CO2-EGR–CPG system to key reservoir and operational parameters. The reservoir parameters included horizontal permeability, permeability anisotropy, reservoir temperature, and pore-size- distribution index; while the operational parameters included wellbore diameter and ambient surface temperature. Using an example of a natural gas reservoir model, we also investigated the effects of different strategies of transitioning from the CO2-EGR stage to the CPG stage on the energy-recovery performance metrics and on the two-phase fluid-flow regime in the production well. The simulation results showed that overlapping the CO2-EGR and CPG stages, and having a relatively brief period of CO2 injection, but no production (which we called the CO2-plume establishment stage) achieved the best overall energy (natural gas and geothermal) recovery performance. Permeability anisotropy and reservoir temperature were the parameters that the natural gas recovery performance of the combined system was most sensitive to. The geothermal power generation performance was most sensitive to the reservoir temperature and the production wellbore diameter. The results of this study pave the way for future CPG-based geothermal power-generation optimization studies. For a CO2-EGR–CPG project, the results can be a guide in terms of the required accuracy of the reservoir parameters during exploration and data acquisition.

Ogland-Hand, J.,

J. Bielicki,

B. Adams,

E. Nelson,

T. Buscheck,

M.O. Saar, and

R. Sioshansi,

The Value of CO2-Bulk Energy Storage with Wind in Transmission-Constrained Electricity Systems, Energy Conversion and Management,

2021.

https://doi.org/10.1016/j.enconman.2020.113548 [Download] [View Abstract]High-voltage direct current (HVDC) transmission infrastructure can transmit electricity from regions with high-quality variable wind and solar resources to those with high electricity demand. In these situations, bulk energy storage (BES) could beneficially increase the utilization of HVDC transmission capacity. Here, we investigate that benefit for an emerging BES approach that uses geologically stored CO2 and sedimentary basin geothermal resources to time-shift variable electricity production. For a realistic case study of a 1 GW wind farm in Eastern Wyoming selling electricity to Los Angeles, California (U.S.A.), our results suggest that a generic CO2-BES design can increase the utilization of the HVDC transmission capacity, thereby increasing total revenue across combinations of electricity prices, wind conditions, and geothermal heat depletion. The CO2-BES facility could extract geothermal heat, dispatch geothermally generated electricity, and time-shift wind-generated electricity. With CO2-BES, total revenue always increases and the optimal HVDC transmission capacity increases in some combinations. To be profitable, the facility needs a modest $7.78/tCO2 to $10.20/tCO2, because its cost exceeds the increase in revenue. This last result highlights the need for further research to understand how to design a CO2-BES facility that is tailored to the geologic setting and its intended role in the energy system.

Adams, B.M.,

D. Vogler,

T.H. Kuehn,

J.M. Bielicki,

N. Garapati, and

M.O. Saar,

Heat Depletion in Sedimentary Basins and its Effect on the Design and Electric Power Output of CO2 Plume Geothermal (CPG) Systems, Renewable Energy, 172, pp. 1393-1403,

2021.

https://doi.org/10.1016/j.renene.2020.11.145 [Download] [View Abstract]CO2 Plume Geothermal (CPG) energy systems circulate geologically stored CO2 to extract geothermal heat from naturally permeable sedimentary basins. CPG systems can generate more electricity than brine systems in geologic reservoirs with moderate temperature and permeability. Here, we numerically simulate the temperature depletion of a sedimentary basin and find the corresponding CPG electricity generation variation over time. We find that for a given reservoir depth, temperature, thickness, permeability, and well configuration, an optimal well spacing provides the largest average electric generation over the reservoir lifetime. If wells are spaced closer than optimal, higher peak electricity is generated, but the reservoir heat depletes more quickly. If wells are spaced greater than optimal, reservoirs maintain heat longer but have higher resistance to flow and thus lower peak electricity is generated. Additionally, spacing the wells 10% greater than optimal affects electricity generation less than spacing wells 10% closer than optimal. Our simulations also show that for a 300 m thick reservoir, a 707 m well spacing provides consistent electricity over 50 years, whereas a 300 m well spacing yields large heat and electricity reductions over time. Finally, increasing injection or production well pipe diameters does not necessarily increase average electric generation.

Garapati, N.,

B.M. Adams,

M.R. Fleming,

T.H. Kuehn, and

M.O. Saar,

Combining brine or CO2 geothermal preheating with low-temperature waste heat: A higher-efficiency hybrid geothermal power system, Journal of CO2 Utilization, 42,

2020.

https://doi.org/10.1016/j.jcou.2020.101323 [Download] [View Abstract]Hybrid geothermal power plants operate by using geothermal fluid to preheat the working fluid of a higher temperature power cycle for electricity generation. This has been shown to yield higher electricity generation than the combination of a stand-alone geothermal power plant and the higher-temperature power cycle. Here, we test both a direct CO2 hybrid geothermal system and an indirect brine hybrid geothermal system. The direct CO2 hybrid geothermal system is a CO2 Plume Geothermal (CPG) system, which uses CO2 as the subsurface working fluid, but with auxiliary heat addition to the geologically produced CO2 at the surface. The indirect brine geothermal system uses the hot geologically produced brine to preheat the secondary working fluid (CO2) within

a secondary power cycle.

We find that the direct CPG-hybrid system and the indirect brine-hybrid system both can generate 20 % more electric power than the summed power of individual geothermal and auxiliary systems in some cases. Each hybrid system has an optimum turbine inlet temperature which maximizes the electric power generated, and is typically between 100 ◦C and 200 ◦C in the systems examined. The optimum turbine inlet temperature tends to occur where the geothermal heat contribution is between 50 % and 70 % of the total heat addition to the hybrid system. Lastly, the CO2 direct system has lower wellhead temperatures than indirect brine and therefore can utilize lower temperature resources.

Hefny, M.,

C.-Z. Qin,

M.O. Saar, and

A. Ebigbo,

Synchrotron-based pore-network modeling of two-phase flow in Nubian Sandstone and implications for capillary trapping of carbon dioxide, International Journal of Greenhouse Gas Control, 103/1031642,

2020.

https://doi.org/10.1016/j.ijggc.2020.103164 [Download] [View Abstract]Depleted oil fields in the Gulf of Suez (Egypt) can serve as geothermal reservoirs for power production using a CO2-Plume Geothermal (CPG) system, while geologically sequestering CO2. This entails the injection of a substantial amount of CO2 into the highly permeable brine-saturated Nubian Sandstone. Numerical models of two-phase flow processes are indispensable for predicting the CO2-plume migration at a representative geological scale. Such models require reliable constitutive relationships, including relative permeability and capillary pressure curves. In this study, quasi-static pore-network modeling has been used to simulate the equilibrium positions of fluid-fluid interfaces, and thus determine the capillary pressure and relative permeability curves.

Three-dimensional images with a voxel size of 0.65 μm3 of a Nubian Sandstone rock sample have been obtained using Synchrotron Radiation X-ray Tomographic Microscopy. From the images, topological properties of pores/throats were constructed. Using a pore-network model, we performed a sequential primary drainage–main imbibition cycle of quasi-static invasion in order to quantify (1) the CO2 and brine relative permeability curves, (2) the effect of initial wetting-phase saturation (i.e. the saturation at the point of reversal from drainage to imbibition) on the residual–trapping potential, and (3) study the relative permeability–saturation hysteresis. The results illustrate the sensitivity of the pore-scale fluid-displacement and trapping processes on some key parameters (i.e. advancing contact angle, pore-body-to-throat aspect ratio, and initial wetting-phase saturation) and improve our understanding of the potential magnitude of capillary trapping in Nubian Sandstone.

Fleming, M.R.,

B.M. Adams,

T.H. Kuehn,

J.M. Bielicki, and

M.O. Saar,

Increased Power Generation due to Exothermic Water Exsolution in CO2 Plume Geothermal (CPG) Power Plants, Geothermics, 88/101865,

2020.

https://doi.org/10.1016/j.geothermics.2020.101865 [Download] [View Abstract]A direct CO2-Plume Geothermal (CPG) system is a novel technology that uses captured and geologically stored CO2 as the subsurface working uid in sedimentary basin reservoirs to extract geothermal energy. In such a CPG system, the CO2 that enters the production well is likely saturated with H2O from the geothermal reser- voir. However, direct CPG models thus far have only considered energy production via pure (i.e. dry) CO2 in the production well and its direct conversion in power generation equipment. Therefore, we analyze here, how the wellhead uid pressure, temperature, liquid water fraction, and the resultant CPG turbine power output are impacted by the production of CO2 saturated with H2O for reservoir depths ranging from 2.5 km to 5.0 km and geothermal temperature gradients between 20 °C/km and 50 °C/km. We demonstrate that the H2O in solution is exothermically exsolved in the vertical well, increasing the uid temperature relative to dry CO2, resulting in the production of liquid H2O at the wellhead. The increased wellhead uid temperature increases the turbine power output on average by 15% to 25% and up to a maximum of 41%, when the water enthalpy of exsolution is considered and the water is (conservatively) removed before the turbine, which decreases the uid mass ow rate through the turbine and thus power output. We show that the enthalpy of exsolution and the CO2-H2O so- lution density are fundamental components in the calculation of CPG power generation and thus should not be neglected or substituted with the properties of dry CO2.

Ezekiel, J.,

A. Ebigbo,

B. M. Adams, and

M. O. Saar,

Combining natural gas recovery and CO2-based geothermal energy

extraction for electric power generation, Applied Energy, 269/115012,

2020.

https://doi.org/10.1016/j.apenergy.2020.115012 [Download] [View Abstract]We investigate the potential for extracting heat from produced natural gas and utilizing supercritical carbon dioxide (CO2) as a working uid for the dual purpose of enhancing gas recovery (EGR) and extracting geo- thermal energy (CO2-Plume Geothermal – CPG) from deep natural gas reservoirs for electric power generation, while ultimately storing all of the subsurface-injected CO2. Thus, the approach constitutes a CO2 capture double- utilization and storage (CCUUS) system. The synergies achieved by the above combinations include shared infrastructure and subsurface working uid. We integrate the reservoir processes with the wellbore and surface power-generation systems such that the combined system’s power output can be optimized. Using the subsurface uid ow and heat transport simulation code TOUGH2, coupled to a wellbore heat-transfer model, we set up an anticlinal natural gas reservoir model and assess the technical feasibility of the proposed system. The simulations show that the injection of CO2 for natural gas recovery and for the establishment of a CO2 plume (necessary for CPG) can be conveniently combined. During the CPG stage, following EGR, a CO2-circulation mass owrate of 110 kg/s results in a maximum net power output of 2 MWe for this initial, conceptual, small system, which is scalable. After a decade, the net power decreases when thermal breakthrough occurs at the production wells. The results con rm that the combined system can improve the gas eld’s overall energy production, enable CO2 sequestration, and extend the useful lifetime of the gas eld. Hence, deep (partially depleted) natural gas re- servoirs appear to constitute ideal sites for the deployment of not only geologic CO2 storage but also CPG.

Ogland-Hand, J.D.,

J.M. Bielicki,

Y. Wang,

B.M. Adams,

T.A. Buscheck, and

M.O. Saar,

The value of bulk energy storage for reducing CO2 emissions and water requirements from regional electricity systems., Energy Conversion and Management, 181, pp. 674-685,

2019.

https://doi.org/10.1016/j.enconman.2018.12.019 [Download] [View Abstract]The implementation of bulk energy storage (BES) technologies can help to achieve higher penetration and utilization of variable renewable energy technologies (e.g., wind and solar), but it can also alter the dispatch order in regional electricity systems in other ways. These changes to the dispatch order affect the total amount of carbon dioxide (CO2) that is emitted to the atmosphere and the amount of total water that is required by the electricity generating facilities. In a case study of the Electricity Reliability Council of Texas system, we separately investigated the value that three BES technologies (CO2- Geothermal Bulk Energy Storage, Compressed Air Energy Storage, Pumped Hydro Energy Storage) could have for reducing system-wide CO2 emissions and water requirements. In addition to increasing the utilization of wind power capacity, the dispatch of BES also led to an increase in the utilization of natural gas power capacity and of coal power capacity, and a decrease in the utilization of nuclear power capacity, depending on the character of the net load, the CO2 price, the water price, and the BES technology. These changes to the dispatch order provided positive value (e.g., increase in natural gas generally reduced CO2 emissions; decrease in nuclear utilization always decreased water requirements) or negative value (e.g., increase in coal generally increased CO2 emissions; increase in natural gas sometimes increased water requirements) to the regional electricity system. We also found that these values to the system can be greater than the cost of operating the BES facility. At present, there are mechanisms to compensate BES facilities for ancillary grid services, and our results suggest that similar mechanisms could be enacted to compensate BES facilities for their contribution to the environmental sustainability of the system.

Walsh, S.D.C.,

N. Garapati,

A.M.M. Leal, and

M.O. Saar,

Calculating thermophysical fluid properties during geothermal energy production with NESS and Reaktoro, Geothermics, 70, pp. 146-154,

2017.

https://doi.org/10.1016/j.geothermics.2017.06.008 [Download] [View Abstract]We investigate how subsurface fluids of different compositions affect the electricity generation of geothermal power plants. First, we outline a numerical model capable of accounting for the thermophysical properties of geothermal fluids of arbitrary composition within simulations of geothermal power production. The behavior of brines with varying compositions from geothermal sites around the globe are then examined using the model. The effect of each brine on an idealized binary geothermal power plant is simulated, and their performances compared by calculating the amount of heat exchanged from the fluid to the plant's secondary cycle.

Our simulations combine (1) a newly developed Non-linear Equation System Solver (NESS), for simulating individual geothermal power plant components, (2) the advanced geochemical speciation solver, Reaktoro, used for calculation of thermodynamic fluid properties, and (3) compositional models for the calculation of fluid-dynamical properties (e.g., viscosity as a function of temperature and brine composition). The accuracy of the model is verified by comparing its predictions with experimental data from single-salt, binary-salt, and multiple-salt solutions.

The geothermal power plant simulations show that the brines considered in this study can be divided into three main categories: (1) those of largely meteoric origin with low salinity for which the effect of salt concentration is negligible; (2) moderate-depth brines with high concentrations of Na+ and K+ ions, whose performance is well approximated by pure NaCl solutions of equivalent salinity; and (3) deeper, high-salinity brines that require a more detailed consideration of their composition for accurate simulation of plant operations.

Adams, B.M.,

T.H. Kuehn,

J.M. Bielicki,

J.B. Randolph, and

M.O. Saar,

A comparison of electric power output of CO2 Plume Geothermal (CPG) and brine geothermal systems for varying reservoir conditions, Applied Energy, 140, pp. 365-377,

2015.

https://doi.org/10.1016/j.apenergy.2014.11.043 [Download] [View Abstract]In contrast to conventional hydrothermal systems or enhanced geothermal systems, CO2 Plume Geothermal (CPG) systems generate electricity by using CO2 that has been geothermally heated due to sequestration in a sedimentary basin. Four CPG and two brine-based geothermal systems are modeled to estimate their power production for sedimentary basin reservoir depths between 1 and 5km, geothermal temperature gradients from 20 to 50°Ckm-1, reservoir permeabilities from 1×10-15 to 1×10-12m2 and well casing inner diameters from 0.14m to 0.41m. Results show that CPG direct-type systems produce more electricity than brine-based geothermal systems at depths between 2 and 3km, and at permeabilities between 10-14 and 10-13m2, often by a factor of two. This better performance of CPG is due to the low kinematic viscosity of CO2, relative to brine at those depths, and the strong thermosiphon effect generated by CO2. When CO2 is used instead of R245fa as the secondary working fluid in an organic Rankine cycle (ORC), the power production of both the CPG and the brine-reservoir system increases substantially; for example, by 22% and 20% for subsurface brine and CO2 systems, respectively, with a 35°Ckm-1 thermal gradient, 0.27m production and 0.41m injection well diameters, and 5×10-14m2 reservoir permeability.

Garapati, N.,

J.B. Randolph, and

M.O. Saar,

Brine displacement by CO2, energy extraction rates, and lifespan of a CO2-limited CO2-Plume Geothermal (CPG) system with a horizontal production well, Geothermics, 55, pp. 182-194,

2015.

https://doi.org/10.1016/j.geothermics.2015.02.005 [Download] [View Abstract]Several studies suggest that CO2-based geothermal energy systems may be operated economically when added to ongoing geologic CO2 sequestration. Alternatively, we demonstrate here that CO2-Plume Geothermal (CPG) systems may be operated long-term with a finite amount of CO2. We analyze the performance of such CO2-limited CPG systems as a function of various geologic and operational parameters. We find that the amount of CO2 required increases with reservoir depth, permeability, and well spacing and decreases with larger geothermal gradients. Furthermore, the onset of reservoir heat depletion decreases for increasing geothermal gradients and for both particularly shallow and deep reservoirs.

Garapati, N.,

J.B. Randolph,

J.L. Valencia Jr., and

M.O. Saar,

CO2-Plume Geothermal (CPG) Heat Extraction in Multi-layered Geologic Reservoirs, Energy Procedia, 63, pp. 7631-7643,

2014.

https://doi.org/10.1016/j.egypro.2014.11.797 [Download] [View Abstract]CO2-Plume Geothermal (CPG) technology involves injecting CO2 into natural, highly permeable geologic units to extract energy. The subsurface CO2 absorbs heat from the reservoir, buoyantly rises to the surface, and drives a power generation system. The CO2 is then cooled and reinjected underground. Here, we analyze the effects of multi-layered geologic reservoirs on CPG system performance by examining the CO2 mass fraction in the produced fluid, pore-fluid pressure buildup during operation, and heat energy extraction rates. The produced CO2 mass fraction depends on the stratigraphic positions of highly permeable layers which also affect the pore-fluid pressure drop across the reservoir.

Adams, B.M.,

T.H. Kuehn,

J.M. Bielicki,

J.B. Randolph, and

M.O. Saar,

On the importance of the thermosiphon effect in CPG (CO2-Plume geothermal) power systems, Energy, 69, pp. 409-418,

2014.

https://doi.org/10.1016/j.energy.2014.03.032 [Download] [View Abstract]CPG (CO2 Plume Geothermal) energy systems use CO2 to extract thermal energy from naturally permeable geologic formations at depth. CO2 has advantages over brine: high mobility, low solubility of amorphous silica, and higher density sensitivity to temperature. The density of CO2 changes substantially between geothermal reservoir and surface plant, resulting in a buoyancy-driven convective current – a thermosiphon – that reduces or eliminates pumping requirements. We estimated and compared the strength of this thermosiphon for CO2 and for 20 weight percent NaCl brine for reservoir depths up to 5 km and geothermal gradients of 20, 35, and 50 °C/km. We found that through the reservoir, CO2 has a pressure drop approximately 3–12 times less than brine at the same mass flowrate, making the CO2 thermosiphon sufficient to produce power using reservoirs as shallow as 0.5 km. At 2.5 km depth with a 35 °C/km gradient – the approximate western U.S. continental mean – the CO2 thermosiphon converted approximately 10% of the energy extracted from the reservoir to fluid circulation, compared to less than 1% with brine, where additional mechanical pumping is necessary. We found CO2 is a particularly advantageous working fluid at depths between 0.5 km and 3 km.

Randolph, J.B.,

M.O. Saar, and

J.M. Bielicki,

Geothermal energy production at geologic CO2 sequestration sites: Impact of thermal drawdown on reservoir pressure, Energy Procedia, 37, pp. 6625-6635,

2013.

https://doi.org/10.1016/j.egypro.2013.06.595 [Download] [View Abstract]Recent geotechnical research shows that geothermal heat can be efficiently mined by circulating carbon dioxide through naturally permeable rock formations -- a method called CO2 Plume Geothermal -- the same geologic reservoirs that are suitable for deep saline aquifer CO2 sequestration or enhanced oil recovery. This paper describes the effect of thermal drawdown on reservoir pressure buildup during sequestration operations, revealing that geothermal heat mining can decrease overpressurization by 10% or more.

Randolph, J.B., and

M.O. Saar,

Coupling carbon dioxide sequestration with geothermal energy capture in naturally permeable, porous geologic formations: Implications for CO2 sequestration, Energy Procedia, 4, pp. 2206-2213,

2011.

https://doi.org/10.1016/j.egypro.2011.02.108 [Download] [View Abstract]Carbon dioxide (CO2) sequestration in deep saline aquifers and exhausted oil and natural gas fields has been widely considered as a means for reducing CO2 emissions to the atmosphere as a counter-measure to global warming. However, rather than treating CO2 merely as a waste fluid in need of permanent disposal, we propose that it could also be used as a working fluid in geothermal energy capture, as its thermodynamic and fluid mechanical properties suggest it transfers geothermal heat more efficiently than water. Energy production and sales in conjunction with sequestration would improve the economic viability of CO2 sequestration, a critical challenge for large-scale implementation of the technology. In addition, using CO2 as the working fluid in geothermal power systems may permit utilization of lower temperature geologic formations than those that are currently deemed economically viable, leading to more widespread utilization of geothermal energy. Here, we present the results of early-stage calculations demonstrating the geothermal energy capture potential of CO2-based geothermal systems and implications of such energy capture for the economic viability of geologic CO2 sequestration.

Randolph, J.B., and

M.O. Saar,

Combining geothermal energy capture with geologic carbon dioxide sequestration, Geophysical Research Letters, 38, L10401,

2011.

https://doi.org/10.1029/2011GL047265 [Download] [View Abstract][1] Geothermal energy offers clean, renewable, reliable electric power with no need for grid-scale energy storage, yet its use has been constrained to the few locations worldwide with naturally high geothermal heat resources and groundwater availability. We present a novel approach with the potential to permit expansion of geothermal energy utilization: heat extraction from naturally porous, permeable formations with CO2 as the injected subsurface working fluid. Fluid-mechanical simulations reveal that the significantly higher mobility of CO2, compared to water, at the temperature/pressure conditions of interest makes CO2 an attractive heat exchange fluid. We show numerically that, compared to conventional water-based and engineered geothermal systems, the proposed approach provides up to factors of 2.9 and 5.0, respectively, higher geothermal heat energy extraction rates. Consequently, more regions worldwide could be economically used for geothermal electricity production. Furthermore, as the injected CO2 is eventually geologically sequestered, such power plants would have negative carbon footprints.

Randolph, J.B., and

M.O. Saar,

Coupling geothermal energy capture with carbon dioxide sequestration in naturally permeable, porous geologic formations: A comparison with enhanced geothermal systems, Geothermal Resources Council (GRC) Transactions, 34, pp. 433-438,

2010.

[Download PDF] [View Abstract]Geothermal energy offers clean, consistent, reliable electric power with no need for grid-scale energy storage, unlike wind and solar renewable power alternatives. However, geothermal energy is often underrepresented in renewable energy discussions and has considerable room for growth. New technology and methods will be critical for future investment, and rapid implementation of new techniques will be critical in ensuring geothermal energy plays a significant role in the future energy landscape world - wide. Here, we discuss a novel approach with the potential to permit expansion of geothermal energy utilization while supporting rapid implementation through the use of exist - ing technologies: geothermal heat use in naturally porous, permeable geologic formations with carbon dioxide as the working heat exchange fluid.

PROCEEDINGS REFEREED

Fleming, M.R.,

B.M. Adams, and

M.O. Saar,

Using sequestered CO2 as geothermal working fluid to generate electricity and store energy, World Geothermal Congress,

2020. [View Abstract]The CO2-Plume Geothermal (CPG) power system can operate either as a baseload power source or as a dispatchable generator, making power when it is needed on the electric grid. Unlike wind and solar, which are intermittent power sources that operate only when the wind blows or the sun shines, geothermal heat is always available and can be extracted as needed to generate electricity. As wind and solar begin to constitute a larger portion of the electricity provided to the grid, there is an increased need to provide flexible power generation that makes up the difference between demand and this varying renewable supply. Thus, CPG is a carbon-neutral, renewable, flexible power generator that can fulfill this need.

Unlike most geothermal technologies, CPG can be extended to be an energy storage system, termed CO2 Plume Geothermal Energy Storage (CPGES). To create one version of a CPGES system, a second shallow reservoir is added to the CPG system. CO2 is stored in this shallow reservoir in an intermediate state after power is generated but before the energy-intensive parasitic loads, which reduce the power plant’s overall output. When the generation and parasitic stages are separated by time, nearly the full gross turbine electric generation can be sent to the grid when power is needed. Later, when electricity is cheap, power is taken from the grid and used to cool (and sometimes pump or compress) the CO2. Thus, CPG is expanded into CPGES, adding energy storage to the electric grid.

In this work, we describe a new type of CPGES, termed Earth Battery Extension II (EBE II), which uses a large surface storage tank, or gasometer, to store the CO2 at near-atmospheric pressure. This permits up 260 MWe of electricity to be generated during the battery discharge phase compared to 2.5 MWe for CPG alone. Additionally, the new CPGES system can be configured to produce solid CO2 (dry ice) that can be sublimated at near atmospheric pressure, providing a -78 °C heat sink that can be used for cooling purposes in general and, specifically, to cryogenically capture CO2 from the air. This CO2 can, in turn, be used to develop more such CPGES systems. If no heat sink is desired, the turbine can be optimized by including (additional) stages that result in increased electric power output without dry ice formation.

Adams, B.M.,

D. Sutter,

M. Mazzotti, and

M.O. Saar,

Combining direct air capture and geothermal heat and electricity generation for net-negative carbon dioxide emissions, World Geothermal Congress,

2020. [View Abstract]In this work, Direct Air Capture (DAC) of CO2 is coupled directly with a sedimentary geothermal system with the goal of creating a stand-alone, carbon-negative CO2 capture system. An isobutane Organic Rankine Cycle (ORC) is used to generate electricity from a 2.5 km deep, 50 mD porous-media reservoir with a temperature ranging from 90°C to 140°C. The heat required by the DAC is extracted directly from the produced geothermal stream. A 1 km2 inverted 5-spot reservoir configuration is used. Four different system configurations are tested, including different ORC configurations and the use of an external electrical supply.

We find that Direct Air Capture and a geothermal cycle can be coupled in a stand-alone power-island to capture up to 0.04 MtCO2 per year with a 140°C reservoir and the given 1 km2 reservoir configuration. When 12 MWe of external power is supplied, possibly from a nearby wind turbine farm or photovoltaic park, the same combined system can capture up to 0.18 MtCO2 per year. If a thirty year system lifetime is assumed, the systems can capture from 1.2 MtCO2 to 5.4 MtCO2 over the system lifetime. Also, as the 5-spot reservoir system is designed to be up-scaled by tiling additional 5-spots together into larger configurations without thermal or pressure interference, we considered coupling a 5 km x 5 km geothermal reservoir with Direct Air CO2 Capture as well. When using this 25 km2 reservoir, the stand-alone power island system captures 1.04 MtCO2 per year while the grid-connected system captures 4.63 MtCO2 per year using 282 MWe of externally supplied electricity.

Additionally, we find that there is a temperature optimum for the geothermal resource at which the ORC and steam generator both provide the required proportions of heat and electricity to the DAC. At higher resource temperatures, additional electricity is needed for the DAC, either from a parallel ORC or from an external source. At lower resource temperatures, necessary additional heat for the DAC is provided via an isobutane Heat Pump (HP). With the current assumption of an adsorption-based DAC process whose heat demand is provided through saturated steam at atmospheric pressure, a temperature of 110°C is most ideally suited. Lastly, we find that most resource temperatures have an electric opportunity cost—the forgone electricity per tonne CO2—of approximately 700 kWe-h per tonne CO2.

Garapati, N.,

B.M. Adams,

J.M. Bielicki,

P. Schaedle,

J.B. Randolph,

T.H. Kuehn, and

M.O. Saar,

A Hybrid Geothermal Energy Conversion Technology - A Potential Solution for Production of Electricity from Shallow Geothermal Resources, Energy Procedia, 114, pp. 7107-7117,

2017. https://doi.org/10.1016/j.egypro.2017.03.1852 [Download] [View Abstract]Geothermal energy has been successfully employed in Switzerland for more than a century for direct use but presently there is no electricity being produced from geothermal sources. After the nuclear power plant catastrophe in Fukushima, Japan, the Swiss Federal Assembly decided to gradually phase out the Swiss nuclear energy program. Deep geothermal energy is a potential resource for clean and nearly CO2-free electricity production that can supplant nuclear power in Switzerland and worldwide. Deep geothermal resources often require enhancement of the permeability of hot-dry rock at significant depths (4-6 km), which can induce seismicity. The geothermal power projects in the Cities of Basel and St. Gallen, Switzerland, were suspended due to earthquakes that occurred during hydraulic stimulation and drilling, respectively. Here we present an alternative unconventional geothermal energy utilization approach that uses shallower, lower-temperature, naturally permeable regions, that drastically reduce drilling costs and induced seismicity. This approach uses geothermal heat to supplement a secondary energy source. Thus this hybrid approach may enable utilization of geothermal energy in many regions in Switzerland and elsewhere, that otherwise could not be used for geothermal electricity generation. In this work, we determine the net power output, energy conversion efficiencies, and economics of these hybrid power plants, where the geothermal power plant is actually a CO2-based plant. Parameters varied include geothermal reservoir depth (2.5-4.5 km) and turbine inlet temperature (100-220 °C) after auxiliary heating. We find that hybrid power plants outperform two individual, i.e., stand-alone geothermal and waste-heat power plants, where moderate geothermal energy is available. Furthermore, such hybrid power plants are more economical than separate power plants.

Garapati, N.,

J. Randolph,

S. Finsterle, and

M.O. Saar,

Simulating Reinjection of Produced Fluids Into the Reservoir, Proceedings of 41st Workshop on Geothermal Reservoir Engineering,

2016. [Download PDF] [View Abstract]ABSTRACT In order to maintain reservoir pressure and stability and to reduce reservoir s ubsidence, reinjection of produced fluids into the reservoir is common practice . Furthermore, studies by Karvounis and Jenny (2012 ; 2014), Buscheck et al. (2015), and Saar et al. (2015) found that preheating the working fluid in shallow reservoirs and then injecting the fluid into a deep reservoir can increase the reservoir life span, the heat extraction efficiency, and the economic gains of a geothermal power plant . We have modif ied the TOUGH2 simulator to enable the reinjection of produced fluids with the same chemical composition as the produced fluid and with either a prescribed or the production temperature . T he latter capability is useful, for example, for simulating injecti on of produced fluid into another (e .g., deeper) reservoir without energy extraction. Each component of the fluid mixture , produced from the production well , is reinjected into the reservoir as an individual source term. In the current study, we investigate a CO 2 - based geothermal system and focus on the effects of reinjecting small amounts of brine that are produced along with the CO 2 . Brine has a significantly smaller mobility (inverse kinematic viscosity) than supercritical CO 2 at a given temperature and thus accumulates near the injection well. Such brine accumulation reduces the relative permeability for the CO 2 phase, which in turn increases the pore - fluid pressure around the injection well and reduces the well in j ectivity index. For this reason, and as injection of two fluid phases is pr oblematic, we recommend removal of any brine from the produced fluid before the cooled CO 2 is reinjected into the reservoir. We also study the performance of a multi - level geothermal system (Karvounis and Jenny, 2012; 2014; Saar et al., 2015) by injection of preheated brine from a shallow reservoir (1.5 - 3 km) into a deep reservoir (5 km). We f i nd that preheating brine at the shallow reservoir extends the lifespan of the deep, hot reservoir, thereby increasing the total power production.

Saar, M.O.,

Th. Buscheck,

P. Jenny,

N. Garapati,

J.B. Randolph,

D. Karvounis,

M. Chen,

Y. Sun, and

J.M. Bielicki,

Numerical Study of Multi-Fluid and Multi-Level Geothermal System Performance, Proceedings World Geothermal Congress 2015,

2015. [Download PDF] [View Abstract]We introduce the idea of combining multi-fluid and multi-level geothermal systems with two reservoirs at depths of 3 and 5 km. In the base case, for comparison, the two reservoirs are operated independently, each as a multi-fluid (brine and carbon dioxide) reservoir that uses a number of horizontal, concentric injection and production well rings. When the shallow and the deep reservoirs are operated in an integrated fashion, in the shallow reservoir, power is produced only from the carbon dioxide (CO 2), while the brine is geothermally preheated in the shallow multi-fluid reservoir, produced, and then reinjected at the deeper reservoir's brine injectors. The integrated reservoir scenarios are further subdivided into two cases: In one scenario, both brine (preheated in the shallow reservoir) and CO 2 (from the surface) are injected separately into the deeper reservoir's appropriate injectors and both fluids are produced from their respective deep reservoir producers to generate electricity. In the other scenario, only preheated brine is injected into, and produced from, the deep reservoir for electric power generation. We find that integrated, vertically stacked, multi-fluid geothermal systems can result in improved system efficiency when power plant lifespans exceed ~30 years. In addition, preheating of brine before deep injection reduces brine overpressurization in the deep reservoir, reducing the risk of fluid-induced seismicity. Furthermore, CO2-Plume Geothermal (CPG) power plants in general, and the multi-fluid, multi-level geothermal system described here in particular, assign a value to CO2, which in turn may partially or fully offset the high costs of carbon capture at fossil-energy power plants and of CO2 injection, thereby facilitating economically feasible carbon capture and storage (CCS) operations that render fossil-energy power plants green. From a geothermal power plant perspective, the system results in a CO2 sequestering geothermal power plant with a negative carbon footprint. Finally, energy return on well costs and operational flexibility can be greater for integrated geothermal reservoirs, providing additional options for bulk and thermal energy storage, compared to equivalent, but separately operated reservoirs. System economics can be enhanced by revenues related to efficient delivery of large-scale bulk energy storage and ancillary services products (frequency regulation, load following, and spinning reserve), which are essential for electric grid integration of intermittently available renewable energy sources, such as wind and solar. These capabilities serve to stabilize the electric grid and promote development of all renewable energies, beyond geothermal energy. Numerical Study of Multi-Fluid and Multi-Level Geothermal System Performance (PDF Download Available). Available from: https://www.researchgate.net/publication/274138343_Numerical_Study_of_Multi-Fluid_and_Multi-Level_Geothermal_System_Performance [accessed Jun 12, 2017].

Garapati, N.,

J.B. Randolph, and

M.O. Saar,

Superheating Low-Temperature Geothermal Resources to Boost Electricity Production, Proceedings of the 40th Workshop on Geothermal Reservoir Engineering 2015, 2, pp. 1210-1221,

2015. [Download PDF] [View Abstract]Low-temperature geothermal resources (<150°C) are typically more effective for direct use, i.e., district heating, than for electricity production. District or industrial heating, however, requires that the heat resource is close to residential or industrial demands in order to be efficient and thus economic. However, if a low-temperature geothermal resource is combined with an additional or secondary energy source that is ideally renewable, such as solar, biomass, biogas, or waste heat, but could be non-renewable, such as natural gas, the thermodynamic quality of the energy source increases, potentially enabling usage of the combined energy sources for electricity generation. Such a hybrid geothermal power plant therefore offers thermodynamic advantages, often increasing the overall efficiency of the combined system above that of the additive power output from two stand-alone, separate plants (one using geothermal energy alone and the other using the secondary energy source alone) for a wide range of operating conditions. Previously, fossil superheated and solar superheated hybrid power plants have been considered for brine/water based geothermal systems, especially for enhanced geothermal systems. These previous studies found, that the cost of electricity production can typically be reduced when a hybrid plant is operated, compared to operating individual plants. At the same time, using currently-available high-temperature energy conversion technologies reduces the time and cost required for developing other less-established energy conversion technologies. Adams et al. (2014) found that CO 2 as a subsurface working fluid produces more net power than when brine systems are employed at low to moderate reservoir depths, temperatures, and permeabilities. Therefore in this work, we compare the performance of hybrid geothermal power plants that use brine or, importantly, CO 2 (which constitutes the new research component) as the subsurface working fluid, irrespective of the secondary energy source used for superheating, over a range of parameters. These parameters include geothermal reservoir depth and superheated fluid temperature before passing through the energy conversion system. The hybrid power plant is modeled using two software packages: 1) TOUGH2 (Pruess, 2004), which is employed for the subsurface modeling of geothermal heat and fluid extraction as well as for fluid reinjection into the reservoir, and 2) Engineering Equation Solver (EES), which is used to simulate well bore fluid flow and surface power plant performance. We find here that for geothermal systems combined with a secondary energy source (i.e., a hybrid system), the maximum power production for a given set of reservoir parameters is highly dependent on the configuration of the power system. The net electricity production from a hybrid system is larger than that from the individual plants combined for all scenarios considered for brine systems and for low-grade secondary energy resources for CO 2 based geothermal systems. Superheating of Low-Temperature Geothermal Working Fluids to Boost Electricity Production: Comparison between Water and CO2 Systems (PDF Download Available). Available from: https://www.researchgate.net/publication/271702360_Superheating_of_Low-Temperature_Geothermal_Working_Fluids_to_Boost_Electricity_Production_Comparison_between_Water_and_CO2_Systems [accessed Jun 12, 2017].

Garapati, N.,

J.B. Randolph,

J.L. Valencia Jr., and

M.O. Saar,

Design of CO2-Plume Geothermal (CPG) subsurface system for various geologic parameters, Proceedings of the Fifth International Conference on Coupled Thermo-Hydro-Mechanical-Chemical (THMC) Processes in Geosystems: Petroleum and Geothermal Reservoir Geomechanics and Energy Resource Extraction,

2015. [Download PDF] [View Abstract]Recent geotechnical research shows that geothermal heat can be efficiently mined by circulating carbon dioxide through naturally permeable rock formations -- a method called CO2 Plume Geothermal -- the same geologic reservoirs that are suitable for deep saline aquifer CO2 sequestration or enhanced oil recovery. This paper describes the effect of thermal drawdown on reservoir pressure buildup during sequestration operations, revealing that geothermal heat mining can decrease overpressurization by 10% or more. Geothermal Energy Production at Geologic CO2 Sequestration sites: Impact of Thermal Drawdown on Reservoir Pressure (PDF Download Available). Available from: https://www.researchgate.net/publication/273193986_Geothermal_Energy_Production_at_Geologic_CO2_Sequestration_sites_Impact_of_Thermal_Drawdown_on_Reservoir_Pressure [accessed Jun 12, 2017].

THESES

Adams, B.M.,

On the power performance and integration of carbon-dioxide plume geothermal (CPG) electrical energy production., Dissertation, University of Minnesota, http://hdl.handle.net/11299/17518, 2015. [View Abstract]CO2 Plume Geothermal (CPG) energy is a method for producing electricity from heat extracted from hot rock layers or reservoirs deep within the earth's crust. CPG is differentiated from other geothermal technologies by several factors: 1) CPG uses CO2 as the primary geologic working fluid instead of brine, 2) CPG utilizes naturally permeable porous reservoirs to extract heat, such as saline aquifers or depleted hydrocarbon reservoirs, 3) CPG is deep--a CPG reservoir must have a depth of 1 km to maintain CO2 in its supercritical state; though depths of 2 to 5 km are more common, and 4) CPG utilizes reservoirs at common geologic temperature gradients, unlike traditional hydrothermal which utilizes shallow reservoirs of unusually high temperature. Thus, CPG is intended to be integrated into an existing CO2 sequestration site affording an economic return on CO2 capture expenses by providing carbon-neutral, dispatchable electricity. Even when CPG is used as a base-load power source, it correlates well with electrical demand, unlike wind and solar (Chapter 5). Typically, CPG configurations consist of one or more injection and production wells. These wells link the surface plant with the porous reservoir to create a fluid circuit. Cooled fluid is injected at the surface, heated within the reservoir, and then returned to the surface at higher temperature and pressure which can then be used to create electricity. The variation in CO2 density between injection and production wells creates a thermosiphon which can drive circulation of CO2 without the use of pumps (Chapter 2). The geologic CO2 can be passed directly through a turbine, called a direct system, or heat can be extracted and used to power an Organic Rankine Cycle, called an indirect system. Either system may be used to generate electricity, although a direct system will nearly always produce more electricity than the indirect system. With reservoirs at moderate depth and temperature, these direct systems will also produce more electricity than comparable brine hydrothermal systems (Chapter 3). The reservoir well spacing and diameter affect the average power and longevity of a CPG system. For every combination of well diameter and reservoir depth, temperature, permeability, and thickness, an optimum spacing between the central injection well and a circumferential collection well will provide the greatest power output over time; placing the collection well too close to the injection well depletes the reservoir too quickly while spacing it too far away increases pressure losses, decreasing the overall power (Chapter 4). Likewise, the selection of too small a well diameter will limit mass flowrate, and thus power, while an oversized well diameter may quickly deplete the reservoir and provide no additional benefit (Chapters 3 & 4). This research has provided a significantly deeper understanding of CPG power systems and their operation. The impact of this work is to establish a basis of CPG research to be used in several ways. It can directly inform industrial developments, such as a green-field implementation of CPG or the long-term planning of a CPG-ready Carbon Capture and Storage site. This work may also be the basis for future economic or policy analyses that can further argue for the development of CPG. Thus, this work will help enable CPG as part of the 21st century energy portfolio.